With the increasing awareness of environmental protection and the demand for resource recycling, pyrolysis equipment is increasingly used in waste treatment, biomass energy conversion and other fields. Our pyrolysis system is suitable for large-scale, high-efficiency waste treatment and resource conversion scenarios. They can meet customers who have high requirements for equipment performance, stability and environmental protection standards.

Pyrolysis of Ship Waste Oil Sludge: A New Approach to Marine Environmental Protection

Waste ship oil sludge refers to the large amount of complex waste oil sludge generated during navigation, maintenance, and oil storage. It mainly originates from oil stains in the engine room hull, fuel purification residue, and lubricating oil replacement waste. Furthermore, due to the unique operating environment of ships, the

Installation of Medical Waste Pyrolysis Equipment in Philippines

By the end of October 2025, Mingjie Group had completed the installation of MJ-15 medical waste pyrolysis equipment in Philippines. The pyrolysis plant operates at high temperatures in an oxygen-free environment. It enables the reduction, harmlessness, and energy recovery of medical waste. The success of a medical waste pyrolysis plant

Plastic Pyrolysis Plants in Europe

Plastic pyrolysis plants have become key equipment for Europe in dealing with 29 million tons of plastic waste annually. They are particularly well-suited for processing contaminated and film plastics that are difficult to recycle mechanically. Plastic pyrolysis plants in Europe have an annual capacity of 150,000 tons of plastic-derived pyrolysis

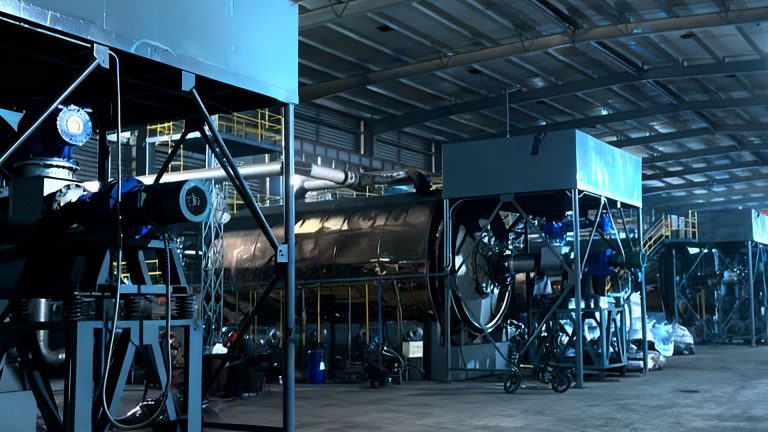

3 Sets MJ-15 Pyrolysis Equipment for Sale to Romania

On October 28, 2025, Mingjie Group completed the shipment of three sets MJ-15 pyrolysis equipment for sale to Romania. We equip these pyrolysis machines with condensation systems, advanced exhaust systems, and control systems. The MJ-15 pyrolysis equipment for sale to Romania features a large furnace door and high processing capacity.

Optimal Oily Sludge Treatment by Pyrolysis Technology

Pyrolysis technology, with its unique advantages, has become a more environmentally friendly and efficient method for oily sludge treatment. Oil sludge pyrolysis involves heating oil sludge at high temperatures in an oxygen-free environment, causing chemical reactions such as cracking and condensation. Pyrolysis plant achieves the reduction, harmlessness, and resource recovery

Bio Charcoal Production Machine for Carbon Neutrality

Driven by technological innovation and policy support, bio charcoal production machine is evolving from simple waste treatment equipment into a multifunctional system that integrates energy recovery and carbon asset management. Biochar is a black, fluffy, carbon-rich solid material produced by pyrolysis, which involves heating biomass to high temperatures (350°C to

Differences Between Making Biochar and Biocoal

Making biochar and biocoal both use biomass as raw materials, but they differ in their core purpose, production process, and end-use applications. The appearance of biochar is more diverse, with common forms being powder, blocks, or irregular granules. It is generally pure black with a metallic luster. Biochar focuses on

Bio Char Making Machine Opens New Energy Future

Bio char making machine produces biochar by heating biomass in an oxygen-deficient environment, the process called biomass pyrolysis. Pyrolysis is a core step in the biochar production process. It involves heating biomass at high temperatures in an oxygen-free or oxygen-deficient environment. During this process, the macromolecular organic matter in the

Installation of Biochar Equipment in South Korea

In October 2025, after the Korean customer received the machine, Mingjie Group immediately arranged professional engineers to guide the installation of biochar equipment in South Korea. The following diagram shows the installation of a biomass pyrolysis plant. Mingjie Group has advantages in technology research and development and biochar equipment applications.

Biochar Making Plant

Biochar making plant is specifically designed to convert biomass into biochar. Its core function is to achieve this transformation through the thermochemical conversion process of pyrolysis and carbonization. Biomass, the raw material for biochar production, comes from a wide range of sources. It includes agricultural waste (straw, rice husks, corn